PRODUCT IDENTIFICATION

Custom Metal Nameplates

Custom nameplates can be fabricated from flexible or metal materials. Screen print, emboss, Metalphoto®, or etch text and graphics onto substrate surfaces. Equipment nameplates can be made to withstand up to 25 years of outdoor exposure and may be die cut, digitally cut, laminated, or machined to your specifications.

Metal Nameplates

Whatever your metal nameplate needs, Prestige MFG can custom design the perfect solution. Our metal identifiers include data and information about weights and equipment specifications. Used in the construction, mining industries, and general equipment manufacturing industries, our nameplates are long-lasting and built to withstand harsh conditions with some products guaranteed for 25 years or more.

MATERIAL & FINISH OPTIONS

ALUMINUM

.005″ – .125″ THICKNESSES

- Bright

- Foil

- Mill Finish

- Brushed Finish

ANODIZED ALUMINUM

.005″ – .125″ THICKNESSES

- Black

- Clear

- Red

- Gold

Metalphoto®

.003″ – .125″ THICKNESSES

- Matte

- Satin

- Satin Gold

BRASS

.020″ – .032″ THICKNESSES

- Brushed Finish

STAINLESS STEEL

.010″ – .035″ THICKNESSES

- 2B Mill Finish

PROCESSES & FABRICATION

- Metalphoto®, Etching, Screenand Digital Printing Available

- Hole Cuts (Any Location) from .05” to 3.5” in Size – varies by material and thickness

- Hole Patterns Machined to Strictest Tolerance

- Up to 25 Year Outdoor Exposure

- UL Listed Products

- Embossing and Forming Capabilities

When your application calls for a material that will remain legible through the harshest of environments, Metalphoto is your go-to material. These industries all trust Metalphoto for their critical identification applications:

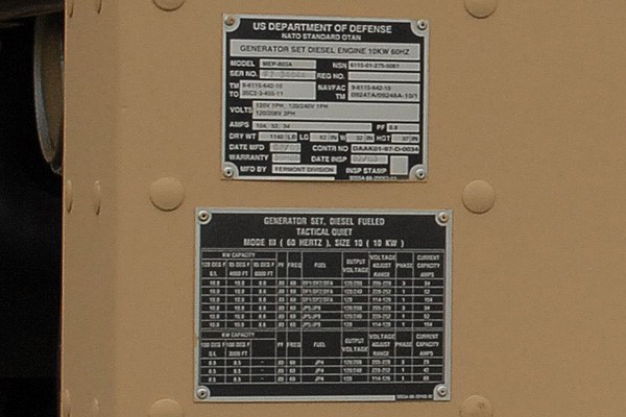

METALPHOTO PROVIDES DURABLE IDENTIFICATION FOR DEFENSE APPLICATIONS

METALPHOTO PROVIDES DURABLE IDENTIFICATION FOR DEFENSE APPLICATIONS

Metalphoto’s durability comes from its image – which is sealed inside of the anodized aluminum, providing resistance to corrosion, sunlight degradation, abrasion, high temperatures and chemical exposure. Its unique, photographic imaging process supports ultra-high resolution images and variable information – including machine-readable barcodes, anti-counterfeit security features and serialized data.

APPLICATIONS

COMPONENT IDENTIFICATION / BARCODE LABELS

EQUIPMENT NAMEPLATES

EQUIPMENT NAMEPLATES

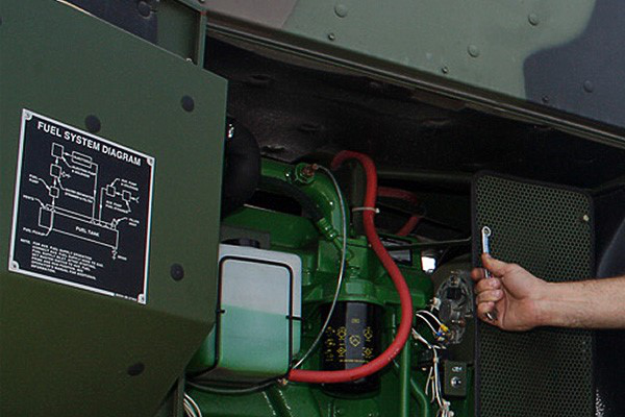

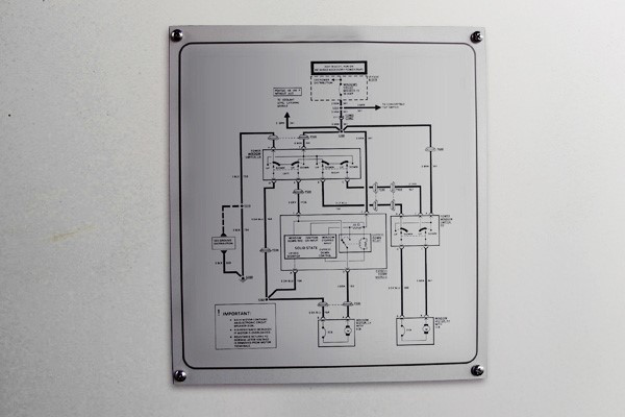

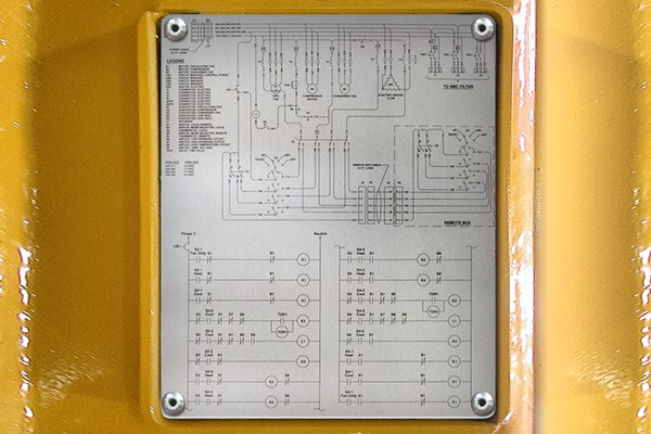

PROCEDURE /MAINTENANCE IDENTIFICATION

PROCEDURE /MAINTENANCE IDENTIFICATION

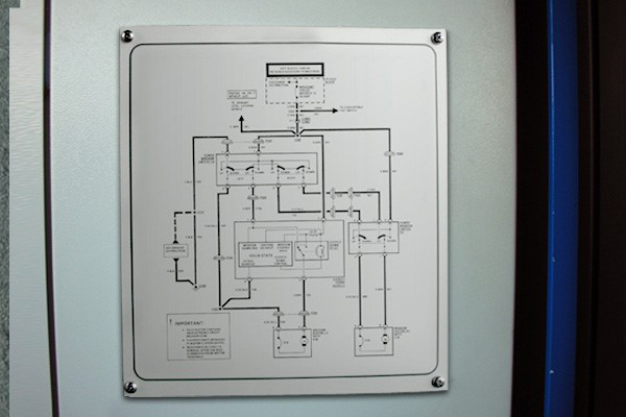

OPERATOR CONTROL PANELS

OPERATOR CONTROL PANELS

INDUSTRY SPECIFICATIONS METALPHOTO MEETS:

- MIL-STD-130N

- MIL-DTL-15024G, Type G or H

- MIL-DTL-19834C (0.003″ foil)

- A-A-50271 Class-2 Composition C

- Federal Specification GG-P-455B

DURABLE IDENTIFICATION FOR AIRCRAFT AND AEROSPACE APPLICATIONS

For over 60 years, engineers have trusted Metalphoto® photosensitive anodized aluminium for extremely durable equipment and process identification items installed in demanding operating environments. Specified by Boeing, Airbus, Lockheed Martin, NASA and the United States Department of Defense, Metalphoto is used for applications such as nameplates, barcode labels, maintenance schematics, operator control panels, safety protocols and many others

APPLICATIONS

COMPONENT IDENTIFICATION / BARCODE LABELS

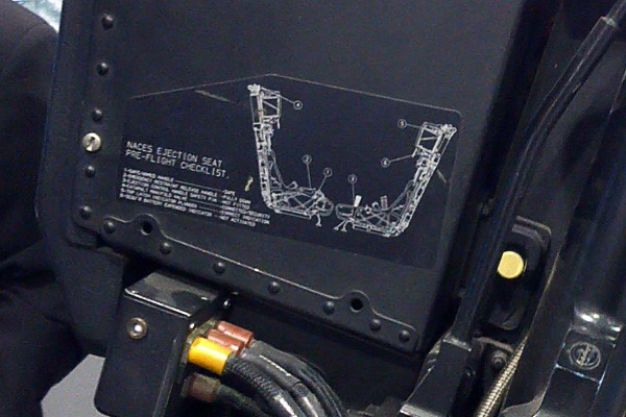

MAINTENANCE SCHEMATICS

MAINTENANCE SCHEMATICS

PROCEDURE IDENTIFICATION

PROCEDURE IDENTIFICATION

OPERATOR CONTROL PANELS

OPERATOR CONTROL PANELS

INDUSTRY SPECIFICATIONS METALPHOTO MEETS:

- Boeing Commercial Aircraft Company, Boeing Process Specification BAC5875, Fabrication of Aluminum Markers, Instrument Panels, Drawer Front Panels and Fabrication of Metal and Plastic Appliques

- Lockheed Martin, LMA-PN010, Fabrication of UID Nameplates for Aircraft Items

- BF Goodrich Aerospace, Data Systems Division, Specification SMT0022

- NASA, Johnson Space Center Texas, Space Station Inventory Label Specification – SSP 50007

- Honeywell, Inc., Satellite Systems Operations, Metalphoto approved for use on Space Station, Memorandum A3-J024-M-9501786, Laboratory Case 161311

THE INTELLIGENT METALPHOTO VIN TAG.

A 20-YEAR TAG FOR A 20-YEAR TRAILER.

The Intelligent Metalphoto® VIN Tag replaces traditional etched plates because of greater durability and optional machine-readable barcodes. Those features create the following benefits for trailer manufacturers and their customers:

BENEFITS TO THE TRAILER MANUFACTURER

- Drive aftermarket revenue – digitally link to sources for OEM aftermarket parts and service.

- Enhance your selling proposition – differentiate your trailer from competitors and offers your customers a series of cost-saving benefits (see below).

- Enhance your brand image – feature a crisp, high-resolution brand logo image that lasts the life of your trailer & demonstrates the quality of your brand.

BENEFITS TO THE FLEET OWNER

- Asset Tracking – end manual data entry with an asset-specific barcode, reducing labor and errors associated with trailer intake at transfer stations and maintenance facilities.

- Asset Maintenance – give the operator and mechanic a service history for each trailer, helping to locate OEM-approved replacement parts and reduce downtime through targeted preventative maintenance.

- Little to No Replacement Costs – its image, which is sealed inside of the anodized aluminum, provides resistance to road-salt corrosion, abrasion and other conditions that can obscure traditional etched steel plates.

- Proven Track Record – used by several leading trailer manufacturers already, the IntelligentMetalphoto VIN Tag is already being deployed by leaders in the industry.

HERE’S HOW IT WORKS:

DURABILITY:

The Intelligent Metalphoto VIN Tag’s durability comes from Metalphoto’s photographic image which is sealed inside of the anodized aluminum, providing resistance to:

- Sunlight degradation (20+ years)

- Road-salt corrosion (30 days in chamber)

- Abrasion (7,000 cycles on tabor abrader)

- High temperatures (1,000°F)

- Chemical exposure (diesel fuel, hydraulic fluid and several others)

RESOLUTION:

The Intelligent Metalphoto VIN Tag supports variable data and barcodes because it is a photographic technology. That means:

- Variable data can be embedded in the plate or punched/scribed your location(s)

- Barcodes reduce data entry errors and time – helping your customer track and maintain your product

- Optional two-dimensional QR code can link mechanics to a maintenance history and parts list of OEM-approved aftermarket parts

- Optional anti-counterfeit features such as watermark and micro-print verify authenticity of your product

In addition to VIN Tags, manufactures use Metalphoto for these permeant identification items:

- CSC Safety Approval Plates

- ISO 6346/BIC intermodal shipping container nameplates

- And other durable nameplates, maintenance schematics and labels

DURABLE IDENTIFICATION FOR SHIPBUILDING & MARINE APPLICATIONS

For over 60 years, engineers have trusted Metalphoto® photosensitive anodized aluminium for extremely durable equipment and process identification items installed in demanding operating environments. Specified by Huntington Ingalls, NASSCO, Newport News, the Norwegian Marine Technology Research Institute (Marintek), the United States Navy and many others, Metalphoto is used in applications where labels and nameplates must survive UV exposure, salt spray, abrasion, heat, fuels, cleaning agents, acids, and lubricants while being produced in a timely and cost-efficient manner.

APPLICATIONS

COMPONENT IDENTIFICATION / BARCODE LABELS

COMPONENT IDENTIFICATION / BARCODE LABELS

EQUIPMENT NAMEPLATES

EQUIPMENT NAMEPLATES

PROCEDURE / MAINTENANCE IDENTIFICATION

PROCEDURE / MAINTENANCE IDENTIFICATION

OPERATOR CONTROL PANELS

OPERATOR CONTROL PANELS

INDUSTRY SPECIFICATIONS METALPHOTO MEETS:

- Norwegian Marine Technology Research Institute (Marintek) corrosion test of anodized aluminum plates – Metalphoto. Report #23.1011.00.0391,

December 8, 1991. - United States Navy Evaluation of Label Plate Material and Attachment Methods Considered of Use on LPD-17. CARDIVNSWC-TR-62-00-05, June 2005.

- United States Navy NAVSEA Corona Division IUID Center Environmental Survivability Testing Report. August 2011.

DURABLE IDENTIFICATION FOR ENERGY APPLICATIONS

For over 30 years, oilfield engineers have trusted Metalphoto® photosensitive anodized aluminium for extremely durable equipment and process identification items installed in demanding on-shore and off-shore operating environments as well as renewable energy systems. Specified by National Oilwell Varco, Seatrax and the United States Navy, Metalphoto material is used for applications such as barcode labels, maintenance schematics, machine control panels, safety protocols and many others.

APPLICATIONS

COMPONENT IDENTIFICATION / BARCODE LABELS

COMPONENT IDENTIFICATION / BARCODE LABELS

MAINTENANCE SCHEMATICS

MAINTENANCE SCHEMATICS

SAFETY PROCEDURE IDENTIFICATION

SAFETY PROCEDURE IDENTIFICATION

OPERATOR CONTROL PANELS

OPERATOR CONTROL PANELS

INDUSTRY SPECIFICATIONS METALPHOTO MEETS:

- Norwegian Marine Technology Research Institute (Marintek) corrosion test of anodized aluminum plates – Metalphoto. Report #23.1011.00.0391, December 8, 1991.

- United States Navy Evaluation of Label Plate Material and Attachment Methods Considered of Use on LPD-17. CARDIVNSWC-TR-62-00-05, June 2005.

- United States Navy NAVSEA Corona Division IUID Center Environmental Survivability Testing Report. August 2011.

DURABLE IDENTIFICATION FOR HEAVY EQUIPMENT APPLICATIONS

For over 60 years, engineers have trusted Metalphoto® photosensitive anodized aluminium for extremely durable equipment and process identification items installed in demanding operating environments. Specified by several leading equipment and defense OEMs, Metalphoto is used for applications such as nameplates, barcode labels, maintenance schematics, operator control panels, safety protocols and many others.

APPLICATIONS

COMPONENT IDENTIFICATION / BARCODE LABELS

COMPONENT IDENTIFICATION / BARCODE LABELS

EQUIPMENT NAMEPLATES

EQUIPMENT NAMEPLATES

PROCEDURE / MAINTENANCE IDENTIFICATION

PROCEDURE / MAINTENANCE IDENTIFICATION

OPERATOR CONTROL PANELS

OPERATOR CONTROL PANELS

INDUSTRY SPECIFICATIONS METALPHOTO MEETS:

- Federal Specification GGP-455B(3)

- MIL-DTL-15024F

- MIL-STD-130